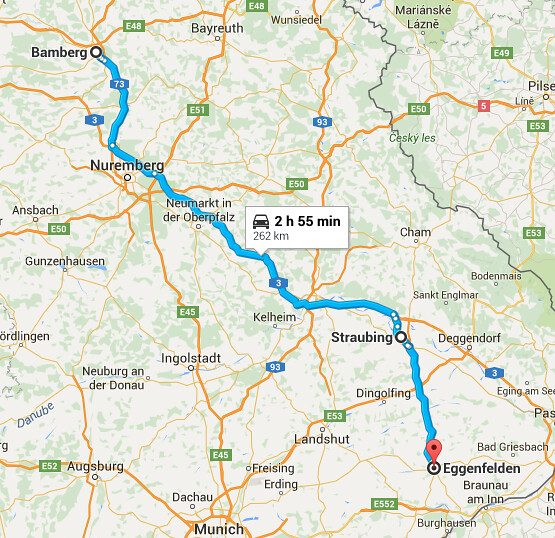

The mission now is fixing the fork at BMW in Bamberg and refreshing the boots at Frey Daytona in Eggenfelden. First we had to ride north to Minsk to get to the closest bridge over the Rhine. Then we took as many of the small roads as possible to get to Bamberg.

Here we took Lulu to the BMW. They had kindly dropped everything to do the work for us. They found a small ding in the metal that we had not seen and sanded it down.

The camping here is quite nice with our tent set up next to the river. One of the quirky things here in Germany is their love of bread. When you check in to a campground here they are so concerned that you order your fresh bread for the morning! We had dropped the bike off at BMW and then took a small tour of the old city. There is a beautiful cathedral in the center. From here we rode back to the campground and towards a HUGE black cloud. We arrived back just a massive thunder and lightening storm hit. It poured for about 20 minutes and then the sun came out again.

We decided to try to get to Daytona as early as possible so started off on the highway.

Arriving in Eggenfelden we headed to Daytona and were greeted by 2 lovely ladies, one of which we found out later is Mrs. Frey! They said that in the 2 days we had they could redo the soles, the tip caps, shift pads, and refresh the leather. They could not do the entire service they provide on the Gortex lining as this takes about a week.

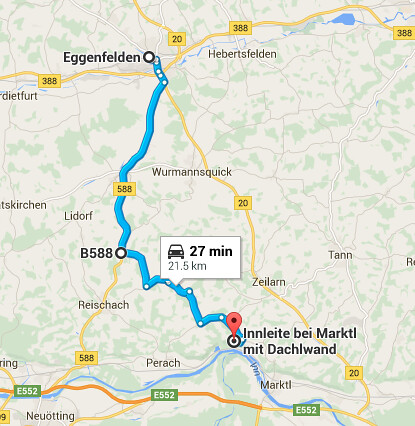

We rode south to near Marktl where there was a nice camp spot near a lake. Again the bread issue was quickly sorted, but because they spoke no English we did end up with pretzels in the morning.

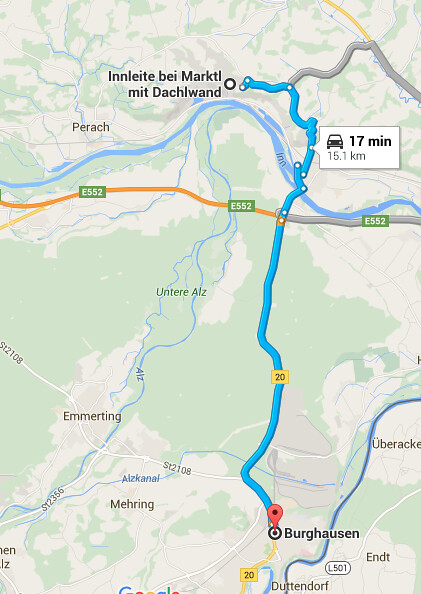

For our day off we rode 25 km south to Burghhausen.

This town has also been a walled fortress city for hundreds of years. There is a lovely old city in the valley and “the worlds longest castle” on the hillside.

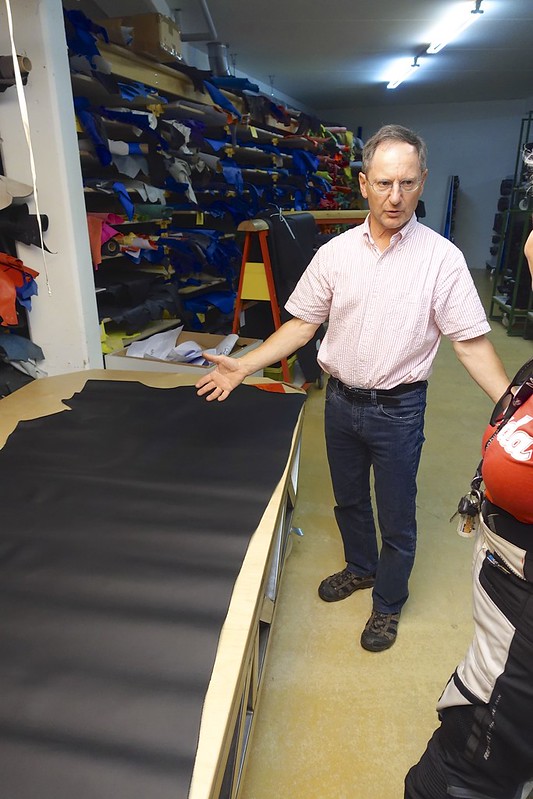

Arriving back at Daytona we were again warmly greeted. We were given our old boots, which now looked new again and asked if we could wait a few minutes for Mr. Frey who wanted to give us a tour of the factory.

We got a tour of the factory and saw how these boots are made from the almost 100 parts in 75 steps. The inner footplate, which is designed for maximum strength while still being flexible for walking is what saved my foot from worse damage in Ecuador. We saw how the leather is cut and sewn. And how the boots are assembled. The boots even have kangaroo leather!

They Frey’s were kind enough to gift us the service on the boots and also some leather care products. This was a very nice surprise. They also posted on their web site about our visit!!!

Thank you for continuing to share your fantastic adventure , with great words and photos !!!

Ride safe

Best wishes

Andrew

Thanks for joining along with us!!!! Sara